Full Description

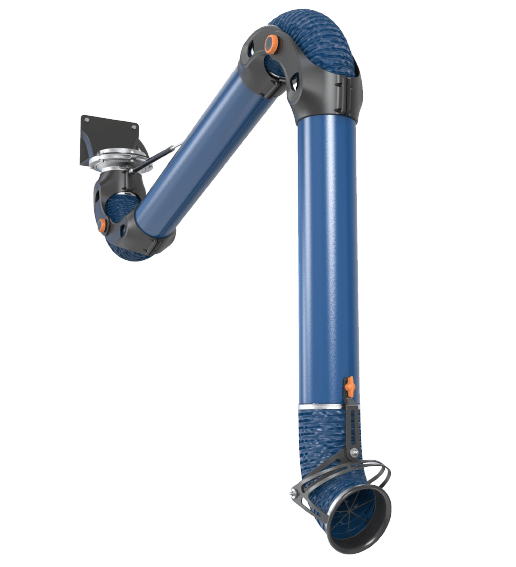

Fume Extraction Arms

Auto Extract System's fume extraction arms offer a wide range of industrial process applications, such as brazing, welding and soldering, for dust and fume extraction and can be used in various working environments, for example, the chemical industry and metal and fabrication industry.

The hose extraction arms are ideal for capturing fumes such as welding, light dust and gases. These have proven to be a very popular and diverse product for our LEV installations as they provide at-source extraction and remove the pollutant from the workplace before it has the opportunity to dissipate into the workplace.

Articulated Extraction Arms

We offer fume extraction arms in a wide variety of lengths, from 2000mm to 9,000mm and can articulate 180° in radius, from the wall or structure fixing, effectively doubling the arm's reach.

. Arms come in different diameters and depend on the airflows required at the capture hood to contain and remove the contaminant at source.

Always Choose a Low Pressure Drop

We've tried and tested many different extraction arms on the market and have found these to be the most robust and highest-quality arms available. The hose extraction arms we install come complete with an external exoskeletal support structure. An external support structure allows for there to be:

- Pressure Drop - A low-pressure drop within the system. Less mechanical parts disturb the airflow, meaning the user will get a better airflow at the capture hood

- Easier to Maintain - Less mechanical seizures mean it's easier to move to the desired capture location, but also easy to clean and maintain. Contaminant capture by the LEV system, such as dust, can easily seize up joints and make it difficult to manoeuvre and service.

- Noise - Less noise disruption from the LEV system ventilation will make the workplace less noisy

- Performance - Our fume extraction arms offer 30% better airflow and 50% static pressure drop than a traditional internal knuckle-type arm

User-Friendly Operation

The user is easily able to operate fume extraction arms as its aided with multiple friction joints and two strong gas-powered struts, which means the user can position the hood exactly where the user wants it. An effortless 4-way hood knuckle joint provides the user with a simple, yet smooth performance. It can operate above and below its mounting height and can be turned through virtually 360°. It can be positioned high or low and has good stability when manoeuvred into position.

Also, fume extraction arms make it easy for the user to operate with a 4-way centre joint, meaning it can easily be tilted up, down, left and right to capture fumes or gases at-source.

What Is an Extraction Arm and How Do They Work?

An extraction arm is a flexible product designed to capture and eliminate hazardous contaminants such as fumes and dust before they enter the airspace breathed in by workers. Due to the health risks associated with fumes, it's critical that the particulates are eliminated before they have the opportunity of entering a person's respiratory system. There are several LEV systems that can be used to extract fumes, of which a fume extraction arm is one of the most popular and best-performing products.

Extraction arms typically consist of a hose connected to a hood. The arms work by positioning the system close to the source of harmful airborne contaminants like dust. As work is carried out and dust particles form, they enter the system via the hood and pass through the hose until they reach a safe point where they can be safely disposed of. Fume extraction arms are excellent options as they are easy to use and can be re-positioned to point at the source of fume emission.

What Contaminants Do Extraction Arms Protect Against?

Fume extraction arms are a highly-efficient LEV solution for capturing and removing a range of harmful particles from the air. These hazardous substances are emitted in workplaces that carry out processes like welding, soldering and brazing, to name just a few examples. When inhaled, these contaminants can be harmful to the human body, causing a range of health issues such as lung damage and even cancer. It is vital that businesses take steps to prevent their employees from becoming ill as a result of working with harmful particles. The types of dangerous airborne contaminants can include welding fumes, exhaust fumes, wood dust, and oil mist.

Design Innovation - The Coanda Effect

The Coanda Effect

The hood is designed for maximum extraction efficiency. It is ideal for capturing welding fume extraction and other hot contaminants. For isothermal (non-hot) contaminants, extraction efficiency can be further improved by taking advantage of the Coanda effect.

The Coanda effect is the phenomenon known to Science where a jet of air clings to a flat surface, such as a table or bench, over a longer length rather than flowing through the room. This innovation enables a greater collection of fumes over a longer length than any traditional type all-round hood. The capture hood features a purpose-built flat base to take advantage of this phenomenon making it ideal for the collection of hot fumes and gases.

Extraction Arm Accessories

Fume extraction arms can be specified with additional accessories, to make it easier for the user to operate the LEV system. Accessories, such as operation control switches, lights (located n the centre of the capture hood to illuminate the workplace) rectangular capture hoods, extension hoses and spark traps.

What Industries Use Extraction Arms?

Extraction arms are used in a wide range of industries where industrial work takes place. Examples of industrial processes can include welding, soldering, brazing, and so on. Workplace environments that conduct processes such as this can be dangerous due to the risks involved. Therefore, any industry that carries out tasks involving hazardous environmental contaminants should make use of an extraction arm. The arms are highly effective at capturing harmful substances, such as fume and dust, and prevent the contaminants from polluting work environments and reaching employees. Industries that use fume extraction arms can include everything from automotive and metalworking to manufacturing, woodworking and education.

What Materials Are Used in Fume Extraction Arms?

The type of materials that are used to manufacture safe and efficient extraction arms can vary. The best arm to use will vary depending on several factors, including whether it is used for welding, brazing and soldering. The arm should be suitable for your specific industry and capable of holding the substances that your workplace encounters. Considerations include how easy the arm is to clean and maintain, and whether it is resistant to certain hazards, such as fires and corrosion. Ultimately, you want an extraction arm that will correctly and safely capture fumes at the source level, ensuring that the toxic fumes are disposed of before they can reach employees and cause serious health issues. At Auto Extract Systems, we mainly deal with three types of extraction arm variants: Standard, White and RF. All of our arms are suitable for capturing non-inflammable contaminants like welding fumes and flue gases. The arms are made of powder-coated steel with anodised aluminium for the arm supports.

Dust Extraction Arms

We also have a range of heavier duty Dust Extraction Arms that are ideal for tougher, more industrial working environments.

What do the HSE State?

Shortly after the reclassification and the enforcement expectations changed, HSE released new guidance for managers. in November 2019, the HSE (Health and Safety Executive) released revised task-specific COSHH guidance for welding, cutting and allied jobs to help managers make sure that exposure to all kinds of welding fume is controlled in the workplace.

On the HSE's website, they have different guidance sheets depending on the task you're undertaking. These include:

- WL0 - Advice For Managers

- WL2 - Welding in Confined/Limited/Restricted Spaces

- WL3 - Welding Fume Control. In this guidance, it recommends: "Using a movable fume capture hood on a flexible extraction arm for large to extra-large workpieces."

Find out more about Welding Fume Extraction page.

The Right Extraction Arm Solution for Your Needs

Auto Extract Systems can help specify and design the right fume extraction arms and additional LEV systems for your requirements. We only use the highest quality products and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

| Request your FREE LEV Site Assessment Today!We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email. We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace! This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments. Request your FREE, no-obligation LEV site assessment today! |

Fume Extraction Arms Data Sheet

We've got datasheet's available! Get in touch today to get your hands on the latest copy of our fume extraction arms data sheet. Scroll down to download...

A Complete LEV System

Fume extraction arms should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes either directly to the atmosphere or depending on the working process, via a filtration unit.

To find out more about our products and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above.

Learn How We Helped Businesses Like Yours

To find out more about the latest LEV installations we've been working on, check out our Case Studies section.

About Us

Auto Extract Systems Ltd is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.