Full Description

Downdraught Benches

Our range of downdraught benches provides a user with a workstation that captures dust and fumes whilst working. They are ideal in industrial working environments for dust and fume extraction and industrial processes, such as, welding and grinding work. They remove harmful substances directly from the operator’s breathing zone.

How do Downdraught Benches Work?

Downdraught benches work by drawing fumes and dust created from the working process downwards or backwards through a perforated work surface. These highly efficient LEV systems are designed to protect workers' and working environments from hazardous fumes and dust produced on the work surface.

An Ideal Solution

Downdraught benches are an ideal solution for a variety of working processes, such as dust extraction, fume extraction, welding and grinding processes. Benches are ideal for small to medium-sized workpieces in a fixed location. However, there are various options available when it comes to specifying a downdraught bench local exhaust ventilation (LEV) system. Downdraught benches double up as workstation too, to allow the user to work on workpieces at a single location.

Downdraught benches offer an effective extraction solution by containing and controlling pollutants to improve air quality in the workplace. Downdraught benches are self-contained units and have few mechanical parts, which mean they require little maintenance. In turn, this means they're incredibly efficient at controlling heavy quantities of hazardous substances.

A downdraught bench can be installed as part of a new or existing centralised LEV system and have various kinds of filtration units specified as air cleaners, such as reverse pulse filtration, shaker filters or wet collectors, depending on the materials being processed. Benches can be installed in succession of one another to allow fabricators in large workshops to work from one complete LEV extraction system.

Advantages of Downdraught Benches

- Processes are contained within a single workstation

- Contaminants are drawn away from the user's breathing zone

- Ideal for small to medium-sized work-pieces

- Can be fitted with back and side panels to further contain the contaminants

- Consistent airflow across the full bench

- Eliminates the need for a capture hood, which needs to repositioned with the workpiece

Our Downdraught and Welding Tables

Our range of Downdraught benches are available with a number of options including opening side panels, fully enclosed models with backdraught as well as ones designed specifically for plasma cutting and also all in one models with integrated fans and filter. Available in 1.2, 1.8 and 2.4 meter width models as standard.

- Easy Maintenance - The differential pressure gauge indicates when the filter requires changing ensuring no downtime and easy overall maintenance

- Easily Fits with Existing Ducting - Compatibility with standard size ducting systems, this enables easy integration into existing ventilation setups.

- Superior Build Quality - Our benches are built with industry in mind and have been rigorously tested to ensure high quality performance that is also built to last.

- Stable worktop for performing work safely

We Have the Right Solution for You

Downdraught benches are a very versatile product and are available in a choice sizes and dimensions. They are a very popular product in our range as they provide at-source extraction and remove the pollutant from the workplace before it has the opportunity to dissipate into the workplace.

What do the HSE State?

Shortly after the reclassification and the enforcement expectations changed, HSE released new guidance for managers. in November 2019, the HSE (Health and Safety Executive) released revised task-specific COSHH guidance for welding, cutting and allied jobs to help managers make sure that exposure to all kinds of welding fume is controlled in the workplace.

On the HSE's website, they have different guidance sheets depending on the task you're undertaking. These include:

- WL0 - Advice For Managers

- WL2 - Welding in Confined/Limited/Restricted Spaces

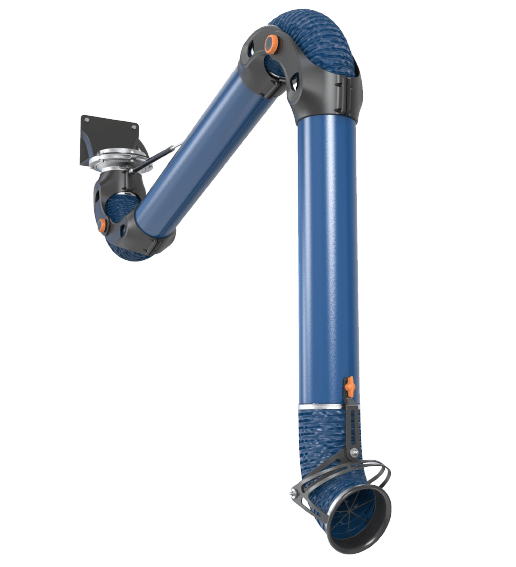

- WL3 - Welding Fume Control. In this guidance, it recommends: "Using a movable fume capture hood on a flexible extraction arm for large to extra-large workpieces."

Find out more about Welding Fume Extraction page.

The Right Downdraught Bench Solution for Your Needs

Auto Extract Systems can help specify and design the right LEV system for your business's requirements. We only use the highest quality products and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

A Complete Complete LEV System

Downdraught benches should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes either directly to the atmosphere or depending on the working process, via a filtration unit.

To find out more about downdraught benches and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above.

Learn How We helped Businesses Like Yours

To find out more about the latest LEV installations we've been working on, check out our Case Studies section.

Request your FREE LEV Site Assessment Today!

We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email.

We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace!

This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments.

Request your FREE, no-obligation LEV site assessment today!

Why Choose Us?

Auto Extract Systems Ltd is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.