Full Description

Wet Collectors & Wet Scrubbers

Wet collectors (commonly known as wet scrubbers too) are designed to capture and filter dust particles. Wet collectors adopt a self, wet scrubbing' motion to wet, capture and filter even the very fine dust particles from the air stream.

A wet extractor provides an efficient and effective way of disposing of obnoxious fumes and dust which arise within the workplace and are manufactured to cope with the heavy burden of flammable dust.

Wet scrubber dust collectors are renowned for their robustness and are unlike many other units available on the market. This is because they have few moving parts, filters or sprays to contend with which allows them to maintain their original suction pressure rates, even under the toughest of conditions.

How Does a Wet Collector Work?

Wet collectors have a fan integrated into the top of each unit. They pull polluted air through an LEV system to capture dust particles through a wet collection method. The wet collector uses centrifugal forces to pull both contaminated air and water up through a series of fixed baffles (or also commonly known as scrubbers) from the water chamber located at the bottom of the unit.

Baffles are shaped as curved blades and as high-velocity air flows through the system, a scrubbing liquid solution curtain (consisting of thousands of water droplets) is created and captures even the finest of dust particles. The scrubbing solution is made up of a mix of water and a biocide to help prevent against legionnaires' disease.

Air is purified by mixing with the dust contaminated water with the scrubbing liquid droplets in the dust collectors to capture dust. As the droplets (containing captured dust particles) collide and are reintroduced with scrubbing solution in the baffles, the dense metal dust fall to the back down the baffles and are collected in the water chamber. An additional filtration layer ensures that small water droplets or water vapour doesn't reach the fan.

Wet dust settles at the bottom of the water chamber and creates a packed bed of sludge. This should regularly be collected, agitated and discharged via the water relief valve to reduce the risk of pressure drops. Clean air is discharged from the top of the unit back into the works atmosphere.

Wet collectors carefully balance the inbound airflow of the LEV system with the water pressure and the fan pressure to harmoniously scrub the air of the finest dust particles.

What Are Wet Scrubbers Used For?

Wet system scrubbers are the ideal solution for filtering and collecting combustible dust produced from processes such as grinding, fettling, linishing, de-burring, polishing and trimming from metals such as Aluminium, Magnesium, Titanium, Zirconium, Lithium and Tantalum. Metal dust generated from these processes is classified as explosive.

Wet collectors mitigate the risk of dust explosions and fires, as if they were to form a cloud, they could ignite. Other combustible particulate matters include a wide range of materials, including, sugar, coal, wood, grain, certain metals, synthetic organic chemicals and any other material that can burn and exists in a fine powdered form. A wet extractor significantly reduces the risk of explosions and fires to keep workers safe - They'll also help you become HSE compliant.

Wet Scrubbers also meets OSHA and NFPA regulations for dust removal located inside buildings, they can recirculate in-plant, tempered air to conserve energy.

What do the HSE State?

In HSE’s HSG103: Safe Handling of Combustible Dust: Precautions Against Explosions, it states that: “Dusty areas will extend far away from the original source of dust release, as air currents will carry the finest of dust particles considerable distances and settle in high and low places. To prevent the dispersion of dust, the HSE recommends a local exhaust ventilation (LEV) system to capture dust at-source.”

Wet collection systems are mandated by NFPA (National Fire Protection Association) Standard 484 2006 regulations for the effective filtration of potentially explosive metal dust. These controls are also often stipulated and required under the Dangerous Substances and Explosive Atmosphere Regulations (DSEAR), the 94/9/EC Directive (also known as 'ATEX 95' or 'the ATEX Equipment Directive') and Control of Substances Hazardous to Health (COSHH) Regulations 2002.

The Right Dust Extraction Solution for Your Needs

Auto Extract Systems can help specify and design the right dust extraction systems for your business's requirements. We only use the highest quality products and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

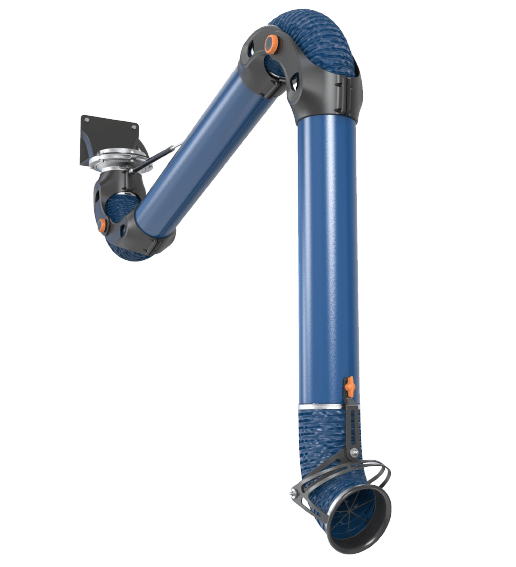

A Complete LEV System

A wet extractor should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes either directly to the atmosphere or depending on the working process. The cleaned air can then be returned to the atmosphere via a high-velocity cowl, as per HSG258: Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV).

To find out more about wet collectors and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request Information button above.

Learn How We helped Businesses Like Yours

To find out more about the latest LEV installations we've been working on, check out our Case Studies section.

Request your FREE LEV Site Assessment Today!

We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email.

We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace!

This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments.

Request your FREE, no-obligation LEV site assessment today!

Why Choose Us?

Auto Extract Systems is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.