Full Description

Reverse Pulse Filters

At Auto Extract Systems, our reverse pulse filters are suitable for industrial filtration processes, for example, welding fume extraction systems where and grinding processes take place.

The reverse pulse jet dust collectors are suited for various kinds of industrial applications and are ideal at handling heavy dust burdens as they work on a continuous process, where there's no or little offline time. Some key features of a reverse pulse unit include:

- Continuous filtration of high dust concentrations

- Better collection than conventional manual shaking

- Automatic cleaning. A differential pressure gauge on either side of the filter ensures the filter is blasted with a jet of air to release dust.

How Does a Reverse Pulse Filter Work?

Dust collectors operate by shooting pulses of compressed air down the cartridge filter media to release captured dust, thus prolonging the life of the filter. The polluted air flows from the inside to out, so dust collected on the inside of the filter unit. The self-cleaning dust and fume extraction dust collectors systems operate by:

- Polluted air enters the filter through the top inlet and dust naturally falls through the filter.

- The filter cartridge removes dust with a high degree of separation.

- Next, a time-controlled diaphragm valve provides high-pressure air pulses through the filter to dislodge dust particles that collect on the cartridge. A specially designed deflector is used to release the same amount of air pressure across the entire cartridge to ensure it's all evenly cleaned.

- Dust particles are dislodged from the filter cartridges to accumulate in the hopper before they're carried down to the dust collector bin.

- The unit features a control panel for on-demand cleaning. Online cleaning means cleaning during operation. Offline cleaning cleans when the plant is not in operation.

- The clean, filtered air is extracted through the air outlet. The outlet connector comes as standard facing downwards, however, (6b) can be directed upwards through the top of the unit.

On-Demand Filter Cleaning

Filters can be set to be cleaned on your terms via several different methods, these include:

- Controlling the pressure from the pressure drop from across the filter cartridges. The pressure drop starts the filter cleaning cycle when the pressure of the cartridge falls below a certain value.

- During online operation - Throughout the working day to ensure there's a stable airflow across all filters during daily operations

- During offline operation - During breaks or the end of the working day when the fan stops. This ensures that smaller, lightweight particles are cleaned from the filter.

Typical Reverse Pulse Filter Set Up

- Control Unit - The cartridges' status can be checked by reading the digital control units, that's located on the side of the filter unit. It can also be checked by installing an external manometer. In addition, remote monitoring on a smart phone's app can be specified too.

- W3-Certified Filters - A CFE W3 must always be monitored using a CFE BW3 warning light placed in a highly visible location indoors.

- Programmable Control Unit - For programming e.g. start-up pressure for cleaning and number of cleaning cycles after the system has stopped.

- Isolating Switch - For electrical connection of the control unit.

- Compressed Air Valve - For setting desired cleaning pressure and fitted with locking shut-off valve. The evacuation valve for the compressed air tank is separate.

- Existing Connections - Only compressed air and single-phase (230 V) electrical connection are required.

Certified For Use

According to standard EN ISO 15012-1 Evacuating the harmful welding fumes directly at the source, (before they dissipate into the wider workplace) is the most effective way of creating a healthy and safe working environment.

The level of harmful and carcinogenic particles in the welding fumes is rising at the same rate as the increase in the percentage of chrome/nickel(Cr Ni) alloys in the welding wire. This means that systems for welding fume extraction and filtration are subject to more stringent requirements. The international standard (EN ISO 15012-1) specifies the requirements for filtering welding fume particles in the following categories.

- W3 - Filtration of welding fumes from steel with a chrome/nickel (Cr Ni) content equal to or greater than 30% must have certified separation of more than 99%.

- W2 - Filtration of welding fumes from steel with a chrome/nickel (Cr Ni) content lower than 30% must have a separation of more than 98%.

How to Maintain a Reverse Pulse Dust Collector

Self-cleaning reverse pulse collectors are very efficient, as they prolong the life of the filter, however, filters still need to be changed from time to time (subjective how often they're used) as the filters quickly become blinded.

The filters are laid horizontally within the unit and are easily accessible during a service. They can also be changed without any contact with the dirty filter.

Technical Specification

We Have the Solution for You

Reverse pulse cartridge filter units provide continuous self-cleaning of the filter cartridges with efficient, power pulses of compressed air down torpedo and aerodynamically designed deflectors to remove the debris built up in the filter media to increase the filter's life expectancy. The high-pressure air cleaning system is governed by a programmable to begin a filter cleaning cycle on-demand during operation.

The Right Dust Extraction Solution for Your Needs

Auto Extract Systems can help specify and design the right LEV system for your business's requirements. We only use the highest quality products and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

Reverse Pulse Filters Data Sheet

We've got datasheet's available! Get in touch today to get your hands on the latest copy of our reverse pulse filter data sheet. Scroll down to download...

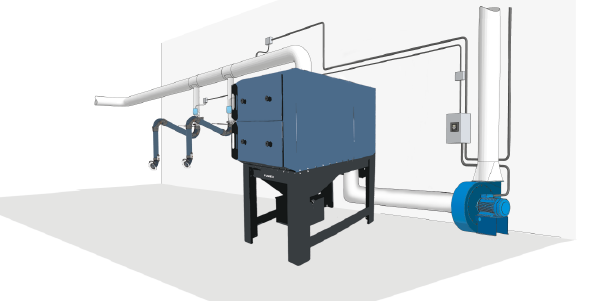

A Complete LEV System

Reverse pulse filters should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes to the reverse pulse filter.

To find out more about reverse pulse filters and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above.

Learn How We helped Businesses Like Yours

To find out more about the latest LEV installations we've been working on, check out our Case Studies section.

Request your FREE LEV Site Assessment Today!

We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email.

We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace!

This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments.

Request your FREE, no-obligation LEV site assessment today!

About Us

Auto Extract Systems Ltd is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.