Full Description

Oil mist extraction systems are used for the capture of metalworking fluids. LEV systems are ideal for extracting the mist and fume generated from metal cutting processes such as lathe turning, milling, drilling, wet grinding and spark suppression (not oil smoke).

Why Do I Need Oil Mist Extraction?

Metalworking fluids are used as a lubricant or coolant to keep parts from wearing. However, one of the inevitable by-products of pumps, compressors, turbines and other machines using oil is oil mist.

Inhaling oil mist is a health hazard, so having it disperse into the workplace reduces the air quality. and can also damage the environment if released into the atmosphere. It can settle and coat machinery and can potentially increase the risk of potential equipment breakdowns. Droplets can also settle on products, staining and potentially contaminating a product, making it unusable.

There are also cost savings to benefit from an oil mist extraction system, as oil that escapes as mist can be captured, filtered and reused.

Oil mist eliminators extract the mist from the immediate vicinity of the machinery, which can benefit your staff, your products, your machinery and your business in various ways.

Oil mist extraction systems are capable of eliminating up to 99.5% of oil particulates from equipment discharge. Extractors operate in a three or four-stage system with replaceable elements. Oil collected can then be returned to the system, reducing oil waste and cutting operating costs.

The oil mist filtration system is built with the modular principle in mind and can easily be expanded to accommodate additional modules. Units have an airflow ranging from 400m3/h to 8,000m3/h with two or three-stage oil mist extraction options.

Where Can You Find Oil Mist?

Oil mist can be found in various industries, including metalworking, automotive, manufacturing, food production, and more. Mist is typically formed when the fluids combine with moving parts during machining. When the mist is formed, it can disperse into the air, causing health and safety risks. Workplaces that use machinery are most at risk of oil mist health hazards.

How Does an Extractor Work?

Oil mist extraction systems remove oil and emulsion mist that is produced when sprayed on to the workpiece during drilling and boring processes. They're sprayed on to the machine tool equipment to cool the metal down from the high temperatures produced.

LEV systems need to be meticulously planned to ensure the airflow extraction rates for oil mist removal is achieved. They extract away any droplets and fumes.

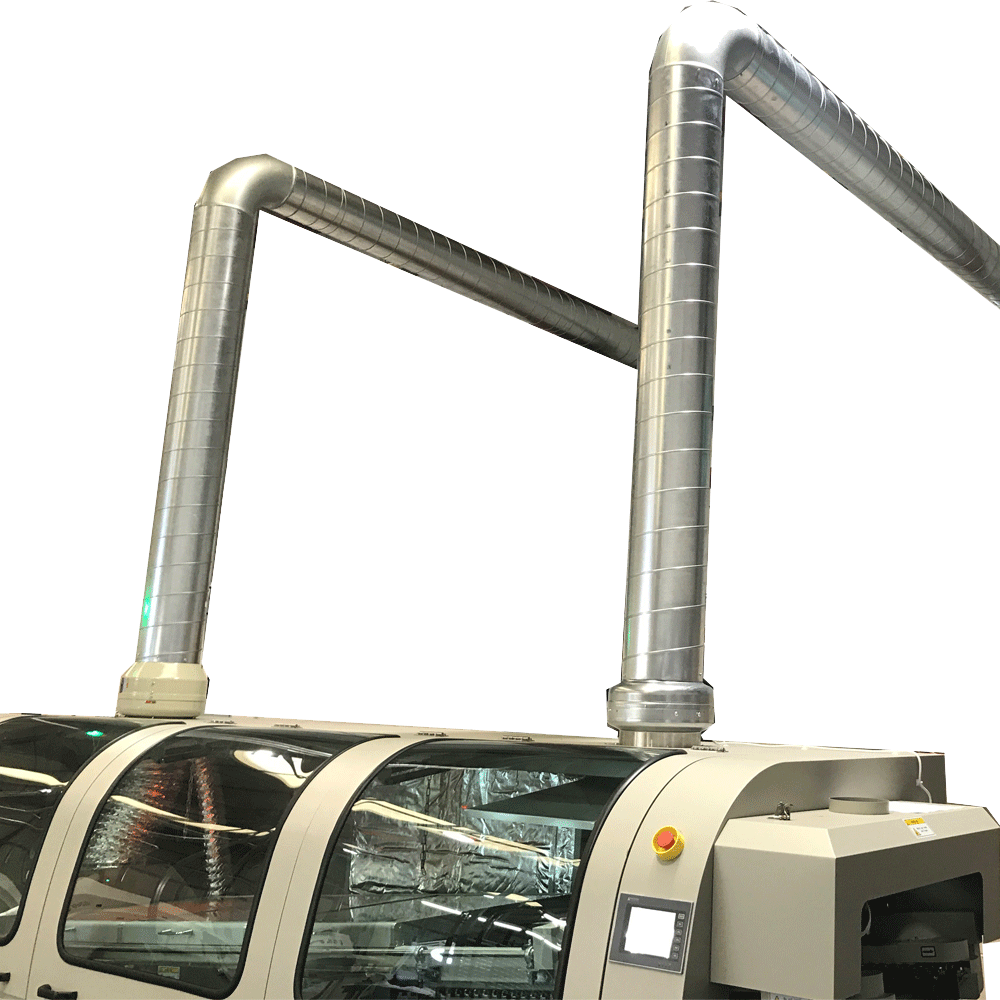

Typical Oil Mist Extraction System Set Up

How Much Does an Oil Mist Extraction System Cost?

There are several factors that influence how much an oil mist extraction system may cost. Examples include the size of your business, what operations your business does, your workplace environment, how many systems you require, and so forth. Therefore, before speaking to you, we are unable to provide an estimate of how much you may pay. Get in touch with our team today to find out more about our extraction solutions. We will be happy to perform a free site assessment where we assess your workplace and recommend a solution that fits best. At Auto Extract Systems, we are committed to offering cost-effective, bespoke solutions that suit our customers best.

What Does the HSE State?

The HSE has several COSHH essential guidance documents to help businesses and duty holders protect employees from metalworking fluids. These can be found on their main Metalworking Fluids page. Here, you'll find a variety of different documents, including Advice for Managers, CNC Machining, Control of Skin Risks During Machining, Sump Cleaning: Water-mix Fluids, Sump Cleaning: Neat Oils and Managing Fluid Quality.

In the HSE's MW1 - COSHH Essentials for Machining and Metalworking Fluids: CNC Machining guidance, it recommends businesses should: "Enclose the machine in as much as possible, for example, retrofit roof panels" and to, "Provide local exhaust ventilation (LEV) to the enclosure. This can either be a standalone unit or a centralised system linking two or more machines.

Whilst in HSE's RR1044 Report: Consultation on Monitoring of Water-miscible Metalworking Fluid (MWF) Mists, discusses the link between the control of metalworking fluid mist and the reduction of respiratory ill health in machining workers, which has been a concern of manufacturers who employ metalworking fluid processes. It goes on to say: How the use of enhanced local exhaust ventilation systems will help minimise the risk.

Evolution of HSE's Metalworking Fluid Guidance

HSE's COSHH essential guidance has come a long way since the older 2011 and 2016 versions. They've become a lot more robust and thought-out. Some key differences include:

- Highlighting the hazard of escaping mist when CNC machine doors open too soon after machining stops

- Controlling the risk to skin, as well as to respiratory risks

- Enclosing CNC machines via retrofitting roof panels

- Stating the method for determining the time delay on enclosed machinery

- Alternative methods to cleaning components via air guns and what to do if air guns are unavoidable

- A better definition of a competent person when it comes to the LEV system documents and testing

- Measures to check the effectiveness of controls are noted as a dust lamp/DRAMS. Also, monitoring the metalworking fluid quality. However, in the new version of MW COSHH essentials guidance, there's no mention of Workplace Air Monitoring, which had been mentioned in previous versions

- Health surveillance for dermatitis, as well as occupational asthma

- IIT to specifically include the understanding of how the LEV system work, how to check whether it's working, when to use air gun alternatives and how to use air guns in a way that minimises exposure.

What Are the Health Risks of Oil Mist Exposure?

Oil mist exposure can cause several health risks to employees, from short-term problems to more severe, long-term issues. The risks and severity depend on various factors like the duration of exposure, concentration, and the specific type of oil. Acute respiratory health issues can include coughing and shortness of breath, while chronic effects may include bronchitis and asthma. Exposure can also cause skin disorders like dermatitis and eye irritation, lung cancer and liver damage. One of the common problems caused by oil mist exposure is extrinsic allergic alveolitis (EAA), also known as hypersensitivity pneumonitis, a group of lung diseases. The symptoms of EAA often include dyspnea, fever, fatigue and weight loss.

The HSE has the following to say about the health risks: "Exposure to metalworking fluids can cause irritation of the skin/dermatitis and lung diseases, such as occupational asthma and occupational hypersensitivity pneumonitis. Metalworking fluid systems that contain water or water mixes can become highly contaminated with harmful bacteria, such as Legionnaires disease. The bacterial contamination of fluids and associated machinery and pipework should be monitored and controlled."

However, the health risks of oil mist aren't limited to respiratory conditions. Oil mist can also be a potential explosive hazard. The HSE has released a report titled 'Area Classification for Oil Mists (MISTS2) - Vertical ignition test report'. This research report was commissioned due to limited information on the conditions that can lead to oil mist being ignited.

We Have the Right Oil Mist Extraction Solution for You

Auto Extract Systems can help provide oil mist-free working environments and provide at-source extraction and remove the pollutant from the workplace before it has the opportunity to dissipate into the workplace.

Extraction Applications

- Lathe machines

- Body-maker oil mist

- Aluminium and Steel scrap waste system exhaust

- CNC machines

Oil Mist Extraction Benefits

- Improve workplace air quality

- Reduce costs from less oil waste

- Healthier working environment and healthier staff

- Protect products from oil mists

The Right Oil Mist Extraction Solution for Your Needs

Auto Extract Systems can help specify and design the right LEV system for your business's requirements. We only use the highest quality products and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

To find out more about oil mist extraction and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request Information button above.

Oil Mist Extraction Data Sheets

We've got datasheets available! Get in touch today to get your hands on the latest copy of our dust extraction arms datasheet. Scroll down to download...

A Complete LEV System

Oil mist extraction systems should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes either directly to the atmosphere or depending on the working process, via a filtration unit.

To find out more about extraction and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above.

What Punishments Can You Expect?

The Health and Safety Executive (HSE) is in charge of protecting the health and well-being of employees, and they have no hesitation in pursuing serious consequences against those that break the rules. If you fail to install an adequate oil mist extraction system or avoid testing and maintaining equipment regularly, you are putting your workers at risk and may face action from the HSE. Usually, breaches will first come with an improvement notice ordering your company to make necessary changes. If you fail to improve your safety procedures, punishment can include a heavy fine, imprisonment and disqualification from managing a company.

One example of a health and safety breach involving oil mist occurred in April 2019 when an employee was splashed in the face and upper body with metalworking fluid. The worker was cleaning a grinding machine while employed for an automotive engineering company. He had an allergic and painful reaction to the fluid touching his skin, causing his skin to become inflamed and broken. Medical advice determined that he would be unable to continue in the role due to the severe health risk. The company was aware of the employee's history of dermatitis but failed to implement control measures to prevent skin contact. They were found guilty of breaching the Health and Safety at Work Act, fined £100,000, and were ordered to pay costs of £639.59.

In another example, an aerospace company was fined £800,000 and ordered to pay costs of £36,912 following an HSE investigation. The company specialises in manufacturing ejection seats and other safety-related equipment for the aviation industry. Three workers at the firm developed extrinsic allergic alveolitis, a group of lung diseases caused by exposure to substances formed by metalworking processes. The conditions cause the alveoli to become inflamed, leading to allergy-related symptoms like coughing, joint pain and shortness of breath. The HSE found that the company didn't do enough to reduce the risk of exposure for the workers, including a lack of extraction to prevent the build-up of mist, no system for cleaning away excess fluid, and a lack of health surveillance procedures.

Learn How We Helped Businesses Like Yours

To find out more about the latest LEV installations we've been working on, check out our Case Studies section.

Request Your FREE LEV Site Assessment Today!

We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email.

We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace!

This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments.

Request your FREE, no-obligation LEV site assessment today!

Why Choose Us?

Auto Extract Systems Ltd is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.