Full Description

Bespoke Fume Extraction Hoods

Bespoke extraction canopies are tailor-made to your exact needs and requirements and are matched with the air flows required to ensure that your business complies with HSE’s 'HSG258: Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV)' regulations and COSHH (Control of Substances Hazardous to Health) 2002 regulations.

Fume extraction canopies have a broad range of applications and can be manufactured out of stainless steel, galvanised steel, polypropylene, PVC or polycarbonate sheet. Extraction canopy hoods for laboratories can be specified too as they are custom-sized to your extract requirements to safely remove the heat of fume out of the workplace.

How do Fume Extraction Hoods Work?

Fume extraction hoods are ideal for processes where contaminants naturally arise, for example, welding fumes, hydrogen from battery charging processes, steam production, heat removal from food manufacturing processes and many more.

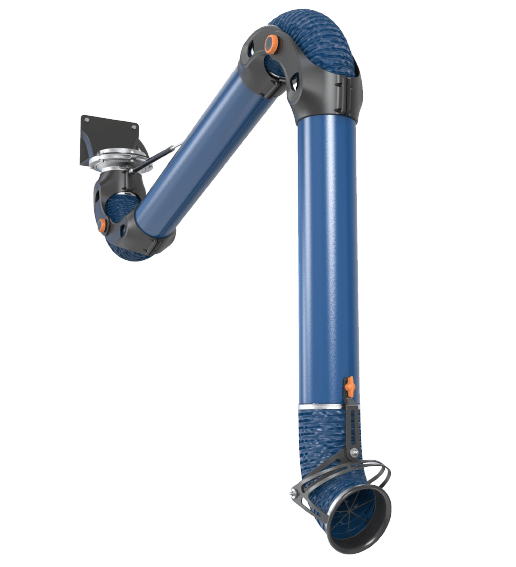

Canopy fume hoods draw fumes inwards and up the canopy and through the extraction system. However, depending on the processes being employed and whether or not the contaminants are passing the worker's breathing zone, an articulated extraction arm may be required. The entrance of the canopies will draw in any residual fume at the extractor hood.

What do the HSE State?

HSE HSG258: Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV) advises that: “Receiving canopy fume extraction hoods should be placed as low and close as possible to the process as practically possible so that the risk of rising fumes dispersing out into the workplace or being affected by through-draughts is reduced.”

Whilst the University of Birmingham describes the receiving capture canopy fume hood as: “The process where the working process provides the energy to deliver the fumes and gases to the canopy hood” (Local Exhaust Ventilation Systems, 2012).

What Materials Are Used to Make Canopy Hoods?

Fume extraction hoods can be made from a wide range of materials. Stainless steel is perhaps the most common choice, but other materials can also include polypropylene, PVC and galvanised steel. The best type of material will depend on the purpose of the canopy hood and the environment in which it will be installed. Typically, hoods should be compatible with the type of chemicals that you intend to capture. Factors to consider include how durable the hood is and whether it is resistant to certain acids and other chemicals. You may also need to consider whether it is resistant to fire, smoke and corrosion. Finally, don't forget to take into account how easy it is to clean and maintain the canopy fume hood.

We Have the Solution for You

Auto Extract Systems can manufacture tailored ‘receiving’ canopy hoods to any required dimensions to suit the requirements of your working processes. We are fully accustomed to specifying and installing receiving extraction canopies hoods (local exhaust ventilation systems) and can assist your business in the safe removal of harmful fumes and gases from your working processes.

The Right Fume and Heat Extraction Canopies for Your Needs

Auto Extract Systems can help specify and design the right LEV system for your business's requirements. We only use the highest quality fume extraction hoods, and installations come complete with a 12-month installation warranty. Find out more about our LEV Installations service.

Extraction canopies should be utilised in conjunction with one of our Dust and fume extractor fans to vent the captured fumes either directly to the atmosphere or depending on the working process, via a filtration unit.

To find out more about welding extraction hoods and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request Information button above.

A Complete LEV System

Bespoke extraction canopies should be utilised in conjunction with one of our centrifugal fans to vent the captured fumes either directly to the atmosphere or depending on the working process, via a filtration unit.

To find out more about bespoke extraction canopies and how we can help you find the right local exhaust ventilation (LEV) system for you and your business, head over to our News section. To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above.

Learn How We helped Businesses Like Yours

To find out more about the latest LEV installations and fume extraction hoods we've been working on, check out our Case Studies section.

Request your FREE LEV Site Assessment Today!

We'll call to arrange a convenient time and date to visit your site. We'll analyse your working processes, assess the substances used and the contaminants generated. We'll work out how best to control the dust and fume in a way that's in line with your COSHH risk assessment. Next, we'll design you a comprehensive LEV system that adheres to HSG258 guidance and send this you to via email.

We'll do all this to ensure we fully understand your dust and fume extraction requirements and help you to provide a pollution-free workplace!

This is an amazing service we do for thousands of businesses throughout the UK and Ireland every year. We work with such a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments.

Request your FREE, no-obligation LEV site assessment today!

Why Choose Us?

Auto Extract Systems Ltd is the UK’s leading Local Exhaust Ventilation (LEV) company. Over the last 20 years, we've helped thousands of businesses create dust and fume free workplaces.

As experts in all things LEV, we can help your business become COSHH (Control of Substances Hazardous to Health) Regulation 2002 compliant with a tailored LEV solution, such as a welding extraction hood. We provide comprehensive design, installation, maintenance and certification services across a range of industry sectors. Find out more about us here.